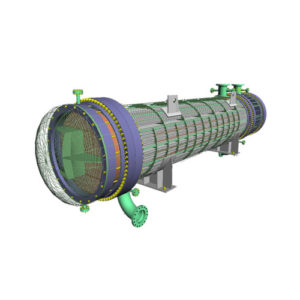

Delivering to a multinational chemical company in Norway

Delivering to a multinational chemical company in Norway

a 905 m² shell and tube duplex heat exchanger with 1569 straight tubes of Ø 38 x 2.5 x 4999 mm.

Have a nice trip!

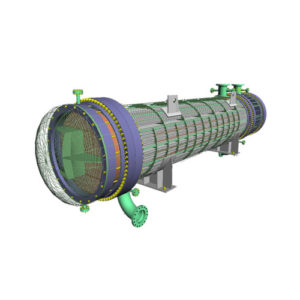

Delivering to a multinational chemical company in Norway

Delivering to a multinational chemical company in Norway

a 905 m² shell and tube duplex heat exchanger with 1569 straight tubes of Ø 38 x 2.5 x 4999 mm.

Have a nice trip!

Work in progress…

Lifting a 350m³ column to finish the work at height. This column has been commissioned by a major Spanish chemical company and is part of a larger set consisting of an 884m² preheater reactor, a 52m³ tank and a 24.7m³ deaeration tank.

Bachiller is delivering an 88m³ evaporator with a circulation pipe of 12.5 m, both made of titanium, commissioned by a chemical company in Switzerland.

Thank you for trusting the quality of Bachiller.

Bachiller designs and manufactures all kinds of tailor-made shell and tube heat exchangers, according to the main international mechanical design codes, using the ultimate design software and according to the particular specifications of the client.

MECHANICAL DESIGN

Bachiller closes a new contract for a 780m² stainless steel reactor, working at 600ºC, for a chemical company worldwide well-known.

Bachiller closes a new contract for a 780m² stainless steel reactor, working at 600ºC, for a chemical company worldwide well-known.

Thanks to our 50 years’ experience and a great effort of our technical team, Bachiller has gained customer’s trust due to our quality, follow-up and support. The equipment is very complicated and will need a lot of study and design of our engineering team.

Delivering a 1,860 m² formaldehyde stirred reactor for a major chemical company in the Czech Republic.

Delivering a 1,860 m² formaldehyde stirred reactor for a major chemical company in the Czech Republic.

Bachiller designs and manufactures all types of stirred reactors in accordance with DIN or ASME regulations, with heating and cooling systems, custom-designed for the process.

Features:

Reactores Agitados de Bachiller

Bachiller closes a new contract for a 53m³ stirred reactor, in titanium Gr.7, for a chemical company worldwide well-known.

Thanks to our 50 years’ experience and a great effort of our technical team, Bachiller has gained customer’s trust due to our quality, follow-up and support. During last year we were offering solutions for best agitation and process that finally result in a new great project and challenge during the whole coming year.

Bachiller closes a new contract with a major Spanish food company for the supply of several pieces of static equipment.

Bachiller closes a new contract with a major Spanish food company for the supply of several pieces of static equipment.

The first one to be supplied is a 3.770m² evaporator with 16 meters tubes.

Bachiller has been awarded thanks to its followup, quality and prices. During 2 years we were offering solutions and assistance that finally result in a new great project and challenge for the coming months.

New contract: Heat Exchanger for a customer in the North of Europe.

New contract: Heat Exchanger for a customer in the North of Europe.

Bachiller closes a new contract for the replacement of a 905m² heat exchanger in duplex material for a chemical company in the North of Europe.

Bachiller has gained again customer’s trust due to quality, support & prices. Another project where we played an important role thanks to the efforts of our whole Bachiller team.

Can Guasch,3 Pol. Ind. Levante

08150 Parets del Vallés

Barcelona (España)

Telf.: +34 93 573 07 70

[email protected]