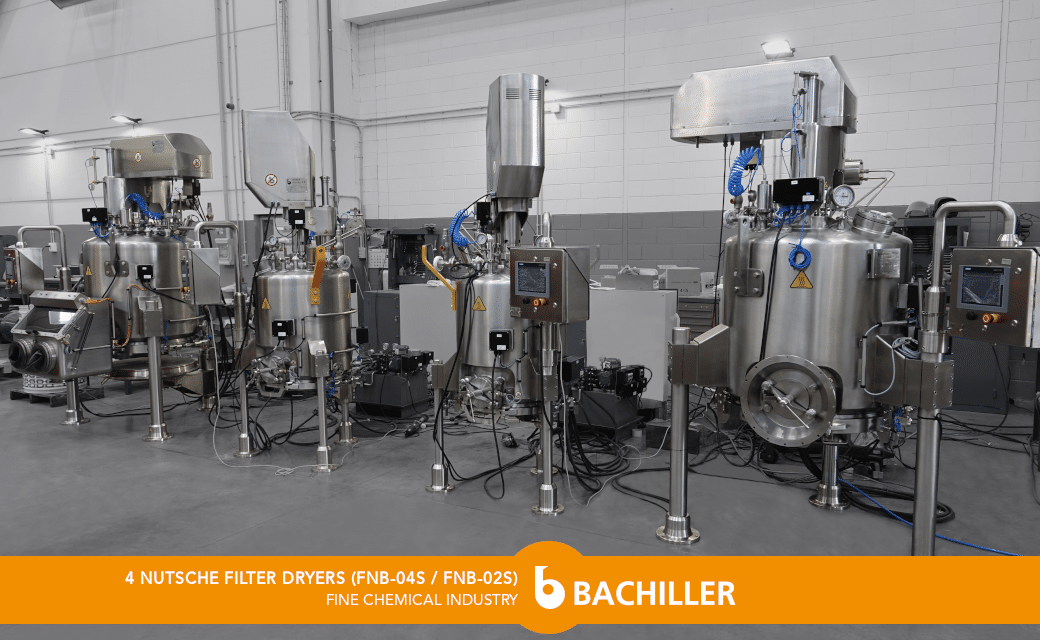

A renowned national company in the fine chemicals sector has trusted Bachiller for the manufacture of four Nutsche Filter Dryers (2x FNB-02S and 2x FNB-04S) in SAF-2205 stainless steel.

In this collaboration, our client was looking for GMP-compliant equipment for its two API production lines. The Nutsche Filter Dryers have proven to be the perfect solution for our client’s needs, allowing all the required processes to be carried out in a single machine and with high efficiency, validated in our laboratory.

A Spanish API manufacturer has relied on Bachiller for the manufacture of a complete turnkey API production plant by the third time.

A Spanish API manufacturer has relied on Bachiller for the manufacture of a complete turnkey API production plant by the third time.

Bachiller signs a new contract for the manufacture of a

Bachiller signs a new contract for the manufacture of a  ADVANTAGES

ADVANTAGES