After these rejuvenating Easter holidays, we’re back with full energy!

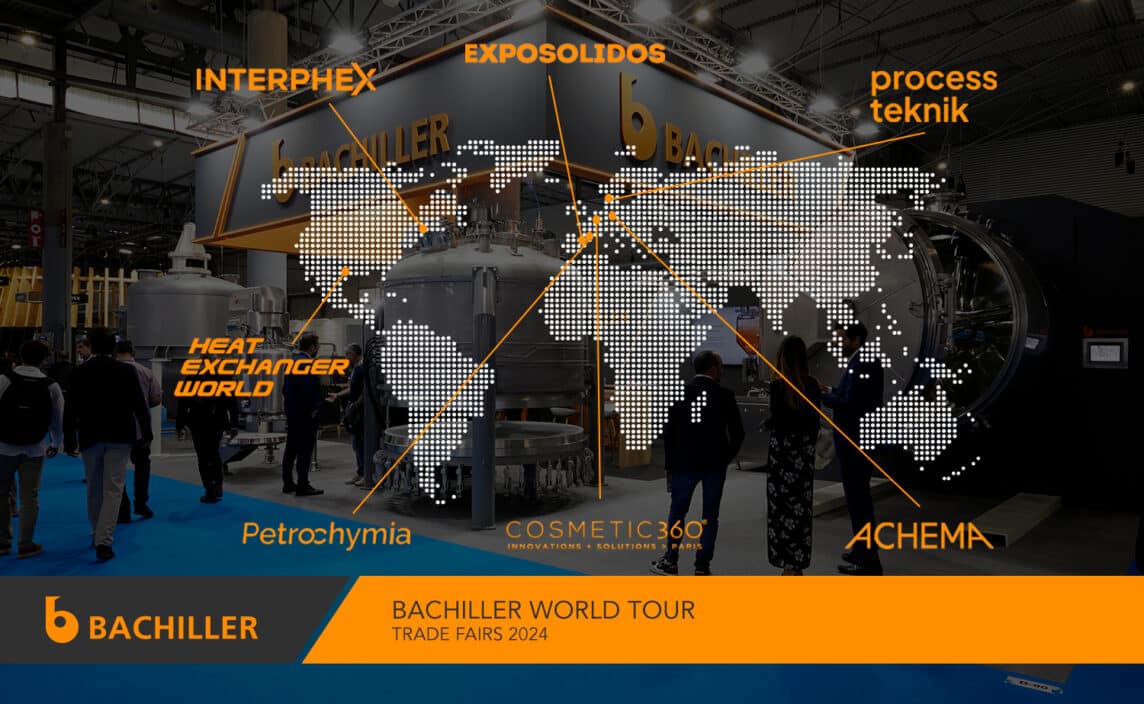

In less than two weeks (April 16-18), we’ll be exhibiting at INTERPHEX Global, held at the Javits Center in New York City. It’s one of the most significant expos in the pharmaceutical and biotechnology sectors worldwide.

Join us at booth 2373, where our team members Marc Comellas Bové and Ivan Bachiller Vial will be delighted to assist you. It’s a fantastic opportunity to discuss how our range of processing and static equipment can support your needs.

We look forward to meeting you there and exchanging insights on how we can collaborate for mutual success. See you at INTERPHEX! 💪